Recent Blog Posts

CNC Machining & Milling Services

Bloomington, MN

We Stand Behind Our Work

Delivery Available

Free Quotes

Hours:

Request Quote

Hero Request Form

Thank you for contacting us.

We will get back to you as soon as possible.

Please try again later.

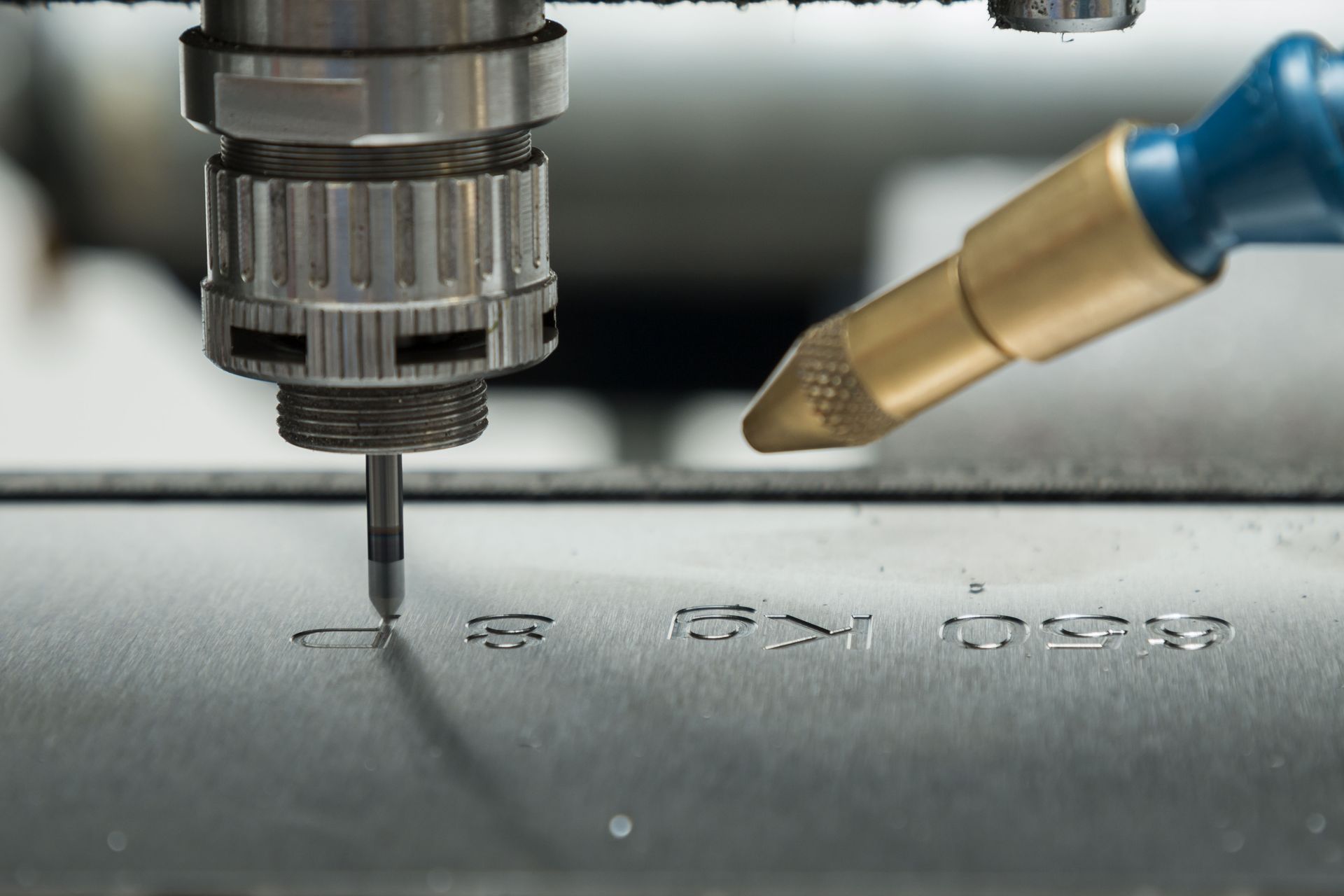

Precision Machining Excellence Since 1976

R.L. Tool, Inc has been a leader in precision machining in Bloomington, MN for over 40 years. We've earned our reputation by consistently delivering outstanding results, fair prices, and excellent customer service. As a family-owned business, we bring a personal approach to each project, ensuring we meet your specific needs with care and precision. Our advanced five-axis machining capabilities and HAAS-trained team allow us to tackle even the most difficult machining projects.

We know that timing is crucial in your industry. That's why we work efficiently, with most parts ready to ship in 4-5 weeks, depending on their complexity. We also provide free quotes within 24 hours for most projects. We don't just make parts; we create solutions that help your business grow. Our wide-ranging material knowledge and teamwork-based design process ensure that every component we produce meets strict quality and precision standards. Call today.

Why Choose R.L. Tool, Inc

Competitive Pricing

Delivery Available

Since 1976

HAAS Trained

Family Owned

Free Quotes

Core Capabilities & Services

R.L. Tool offers a wide range of machining services to meet your various needs. Our main services include precise CNC milling and turning, with our modern five-axis machining technology allowing us to create complex shapes with great accuracy.

We also offer prototyping services, helping you quickly turn your ideas into reality. Our team is skilled in both small and large production runs, maintaining consistent quality no matter the batch size.

Industries We Serve With CNC Machining

At R.L. Tool, we serve many industries with our CNC machining skills. From aerospace and electronics, our varied abilities allow us to meet the strict requirements of different sectors.

We have special knowledge in making parts for industrial machinery, renewable energy systems, and defense applications. Our ability to work with many types of materials, along with our focus on precision and quality, makes us a trusted partner across numerous industries.

Here's what our satisfied customers are saying...

At R.L. Tool, Inc., we take pride in providing exceptional machine shop services to our customers. We would be grateful if you could share your thoughts about our business with others. Your feedback helps us improve and helps others make informed decisions. Please take a moment to leave a review of R.L. Tool, Inc. and let others know what you think.

FAQs

How do you help customers determine whether a part is feasible to machine?

Our team reviews your drawings, tolerances, material specifications, and intended function to confirm whether the part can be manufactured efficiently and accurately. We analyze geometry, tool access, structural requirements, and whether certain features may require design adjustments. Many companies comparing CNC machine mill and turning shops in Minneapolis, MN appreciate this collaborative approach because it allows them to refine parts early, reduce manufacturing costs, and ensure the final component is practical for long-term production.

Can you explain how tolerance requirements impact machining time and cost?

Tighter tolerances often require slower machining speeds, specialized tooling, additional inspection steps, and more controlled setups. These factors increase precision but also influence turnaround time and pricing. When customers work with CNC machine mill and turning shops in Minneapolis, MN, understanding tolerance implications helps them balance functionality, manufacturability, and project budgets. We guide clients toward tolerance choices that ensure performance without unnecessary expense.

How do you verify that complex parts maintain accuracy across multiple machining operations?

Accuracy is preserved through controlled fixturing, repeatable setups, and precision measurement tools such as CMMs, height gauges, and optical comparators. When components require multiple operations, we use reference datums and consistent alignment techniques to ensure continuity across machining stages. Many manufacturers seeking CNC machine mill and turning shops in Minneapolis, MN rely on these processes to achieve uniformity in parts with intricate dimensions and demanding geometrical relationships.

Do you help customers choose the best material for their application before manufacturing begins?

Yes, we provide guidance on machinability, strength requirements, corrosion resistance, heat tolerance, and cost considerations. Choosing the wrong material can lead to premature wear, performance issues, or excessive machining time. Companies searching for CNC machine mill and turning shops in Minneapolis, MN value this early-stage support because material selection directly affects manufacturability and long-term durability of the final part.

How do you maintain consistency when producing repeat orders or multi-year production runs?

We document tooling setups, program revisions, material specifications, and inspection procedures for every job. This documentation ensures repeatability even years later. By keeping all machining programs archived and quality records readily available, we deliver identical components regardless of production date. Businesses evaluating CNC machine mill and turning shops in Minneapolis, MN often choose partners with robust tracking systems that guarantee consistency across long-term projects.

Can you machine parts that require both turning and multi-axis milling in a single workflow?

Yes, our equipment and programming capabilities allow us to blend turning operations with advanced five-axis milling. This reduces setups, improves accuracy, and enables the creation of complex surfaces. Customers looking for CNC machine mill and turning shops in Minneapolis, MN appreciate having access to hybrid machining workflows that allow the production of intricate, high-performance parts in fewer steps.

How do you help customers reduce machining time without sacrificing part quality?

We analyze toolpaths, optimize programming strategies, adjust speeds and feeds, and identify design elements that could be modified without affecting performance. Sometimes minor changes—such as easing sharp internal corners or adjusting wall thickness—can drastically improve efficiency. Many clients searching for CNC machine mill and turning shops in Minneapolis, MN rely on this strategic input to shorten production cycles while maintaining the precision their parts demand.

Can you machine prototypes that are later converted into full production runs?

Yes, our workflow allows seamless transitions from prototype creation to scaled manufacturing. During prototyping, we test manufacturability, tolerance feasibility, and material performance. Once approved, we build fixture sets and production-ready programs to ensure smooth scaling. This process is one reason companies comparing CNC machine mill and turning shops in Minneapolis, MN choose long-term partners who can support every stage of a product’s development.

Do you assist customers in choosing the proper surface finish for their parts?

Absolutely. Surface finish plays a critical role in friction, wear resistance, sealing performance, cosmetic needs, and post-processing compatibility. We discuss options such as bead blasting, polishing, anodizing, coating, and precision grinding depending on the part’s function. Companies evaluating CNC machine mill and turning shops in Minneapolis, MN benefit from this guidance because a proper finish enhances both usability and longevity.

How do you ensure efficiency when machining parts with intricate internal features?

We use specialized tooling, deep-reach strategies, toolpath optimization, and synchronized motion control to reach internal geometries while minimizing tool deflection. Material choice also affects technique, so we tailor the approach to each job. Those exploring CNC machine mill and turning shops in Minneapolis, MN value this capability because internal features often dictate functional performance and cannot be compromised.

Can you collaborate directly with engineering teams during the planning stages?

Yes, early collaboration helps streamline manufacturing, eliminate potential design conflicts, and reduce revisions. We discuss tolerances, machining paths, structural layouts, and potential cost-saving adjustments. Companies that regularly work with CNC machine mill and turning shops in Minneapolis, MN appreciate having machining experts involved early to avoid issues that may not be obvious during initial CAD design.

Do you provide detailed inspection reports for customers who require documented quality verification?

Yes, we offer inspection reports that may include dimensional data, measurement certifications, material traceability, and compliance records depending on your industry. Clients in aerospace, defense, and energy often require thorough documentation. Many who partner with CNC machine mill and turning shops in Minneapolis, MN prioritize companies that can provide comprehensive reporting to meet regulatory and customer-specific requirements.